In the world of fine gemstones, the true value of a sapphire is not defined only by its final brilliance, but by the decisions made long before the first facet is polished. The cutting journey—from natural rough to finished gemstone—is where experience, restraint, and respect for the material determine the outcome. This article documents the full cutting journey of two carefully selected parcels of natural, unheated Ceylon sapphire rough, sourced directly from multiple mining regions in Sri Lanka and transformed through a deliberate, weight-and-beauty-balanced cutting approach.

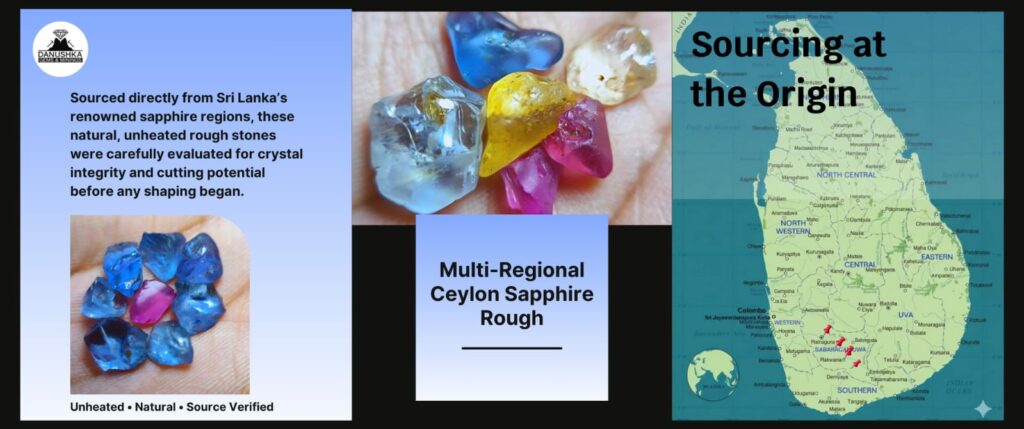

Sourcing at the Origin: Multi-Regional Ceylon Sapphire Rough

Both sapphire parcels were sourced directly from village-level mining areas in Sri Lanka, including Ratnapura, Pelmadulla, Rakwana, Rambuka, and Kolonna village around mining in Sri Lanka. These regions are historically known for producing sapphires with stable crystal structures, balanced color saturation, and strong cutting potential.

All stones were obtained in their natural, unheated condition, with no chemical or thermal enhancement at any stage prior to cutting. Each piece was evaluated individually for crystal integrity, internal features, and realistic yield expectations before any shaping decisions were made.

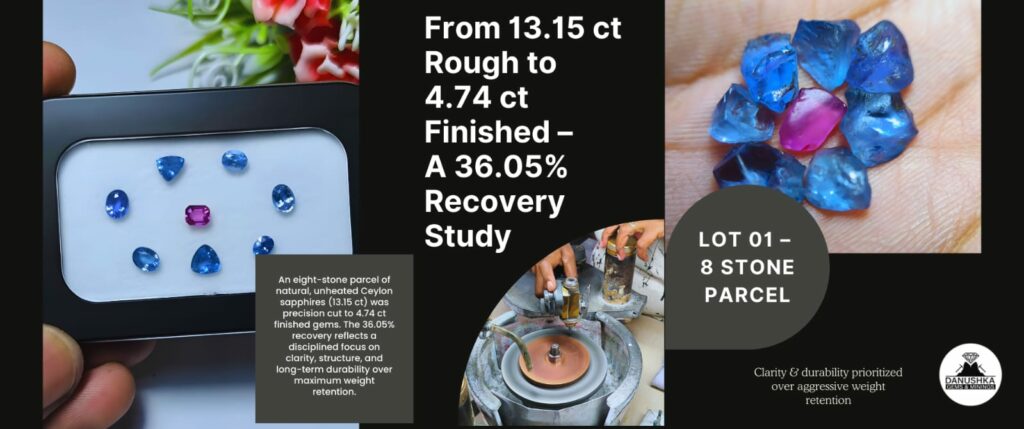

Lot 01: Eight-Stone Parcel – Controlled Yield with Structural Integrity

Lot 01 consisted of 8 pieces of facet-grade Ceylon sapphire rough, totaling 13.15 carats, with individual stone sizes ranging from 2.50 ct to 1.00 ct. The parcel included 7 blue sapphires and 1 pink sapphire, all natural and unheated.

Before cutting, each stone was pre-formed and shaped by Danushka Gems & Mining, focusing on removing only unstable surface areas while preserving core mass. The cutting strategy requested by the customer emphasized a balanced priority between weight retention and visual beauty, while selectively prioritizing clarity for stones that structurally allowed it.

After cutting and polishing, the final total weight achieved from Lot 01 was 4.74 carats, distributed across multiple finished shapes including oval, trilliant, cushion, and octagon. The yield reflects realistic recovery for fine sapphire rough when clarity and long-term durability are prioritized over aggressive weight preservation. resulting in a 36.05% recovery rate.

Lot 02: Seven-Stone Parcel – Adaptive Decisions Without Waste

Lot 02 consisted of 7 pieces of natural, unheated sapphire rough, totaling 16.40 carats, with individual sizes ranging from 5.55 ct to 1.40 ct. The color range in this parcel was diverse, including cornflower blue, pink, yellow, white, and champagne sapphires, all sourced from Rakwana and Ratnapura village around mining in Sri Lanka.

A notable stone in this parcel was a 3.65 ct yellow sapphire rough that displayed a visible center crack. Rather than forcing a single compromised cut, the stone was carefully studied and softly split along its natural internal line, resulting in two clean, usable pieces of 2.25 ct and 1.38 ct. This decision eliminated waste while increasing cutting flexibility and preserving clarity potential.

Following cutting, Lot 02 yielded a final total weight of 4.56 carats, again reflecting a disciplined approach focused on structural stability, clarity, and long-term wearability rather than maximum carat retention. giving a 27.80% recovery rate.

Cutting Philosophy: Weight, Beauty, and Clarity in Balance

All stones across both parcels were cut according to customer-requested priorities, which varied between:

Balanced weight and beauty cutting

Selective clarity prioritization for specific stones

Shape optimization based on natural crystal geometry

Rather than forcing standardized cuts, each stone dictated its own final shape. Oval, trilliant, cushion, and octagon forms were chosen only where the rough naturally supported those outlines.

The full cutting and polishing process was carried out by Mr. Thilakarathne, with all pre-forming and structural planning handled by the owner of Danushka Gems & Mining. This separation of planning and execution ensured that each decision was grounded in both gemological knowledge and hands-on cutting experience.

Certification and Final Verification

Upon completion, all finished stones were certified by GIA and AIGS graduate gemologists, confirming:

Natural origin

Unheated condition

Accurate weight, measurements, and identification

No post-cut enhancement was applied at any stage. The final gemstones represent true Ceylon sapphire character—documented, traceable, and transparently processed.

Conclusion: Why the Cutting Journey Matters

This cutting journey demonstrates that fine sapphire results are achieved not by shortcuts, but by restraint. From village-level sourcing to final certification, every step prioritized honesty, material respect, and realistic outcomes. The final stones are not only beautiful—they are stable, wearable, and true to their origin.

In an industry where over-processing often hides the story of a gemstone, these sapphires remain what they were meant to be: natural Ceylon sapphires shaped by experience, not forced by expectation.